LNCO is involved in the field of supplying consumable equipment for Oil & Gas Drilling Industries.

1: Oil and Gas Drilling Equipment

1.1: Well Head Equipment

1.2: Down Hole Equipment

1.1.1: Well Head Equipment and Rig Drilling Tools

Oil and gas drilling rig equipment such as: Crown Block، Derrick، Subbase، Draw works، Rotary Table، Mud Pumps، Power Generator، Blow Out Prevention (BOP) ،Commy Unit،Travelling Block ،Top Drive and Kelly.

|

|

|

Rotary Table |

Some of the Drilling Rigs Components |

1.1.2: Well Head Equipment ( X- Mass Tree )

After the oil and gas wells are closed, for controlling and exploits the well, number of equipment are used directly on the Top of the well ( X – Mass Tree ) or around the well with connection to the well head ( X- Mass Tree ).

(X-Mass Tree) components:

-

Base Flanges

-

Side Valves

-

Bottom Main Valve

-

Top Main Valve

-

Surface Safety Valve

|

|

|

X-Mass Tree |

X-Mass Tree |

1.2: Downhole Equipment:

Downhole Drilling equipment used in the oil and gas wells are as follow: Drill Bits,Drill Pipes, Heavy weight Drill pipes ,Drill collar ,Jar Pipes , Stabilizers, casings, Pup Joints, Tubings,Liner, and PDM.

Our company is more involved in supplying those Downhole equipment which are consumable as follows:

The following brands are the most important manufacturers of drill bits,as table:1

Table1:List of drilling bits manufacturers

|

Varel |

Smith |

Haliburton |

Reed Hycalog |

Hughes Christensen |

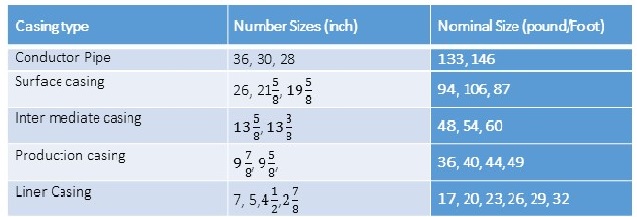

1.2.2:Casing Types

Casing Types are classified according to Table 2

Table2:Specifications and Nominal Sizes

Casings are available in various degrees according to Table3 ,API standard

Table3: specifications of casing grades

|

C75 |

K55 |

H40 |

Q125 |

P110 |

C95 |

C90 |

N80 |

L80 |

J55 |

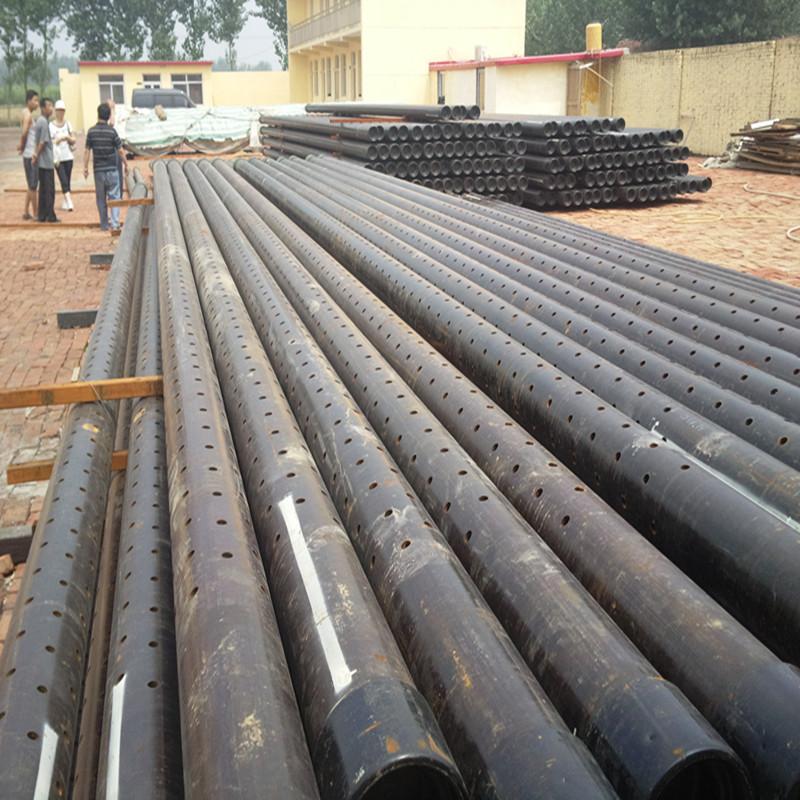

There are some Casings and Liners in below pictures:

Casings are used to prevent fragile formation whenever we are drilling formation. Liner is a kind of casing that doesn’t com to the surface. Liner hang in intermediate casing and suspend by a set of packer and slips to liner hanger

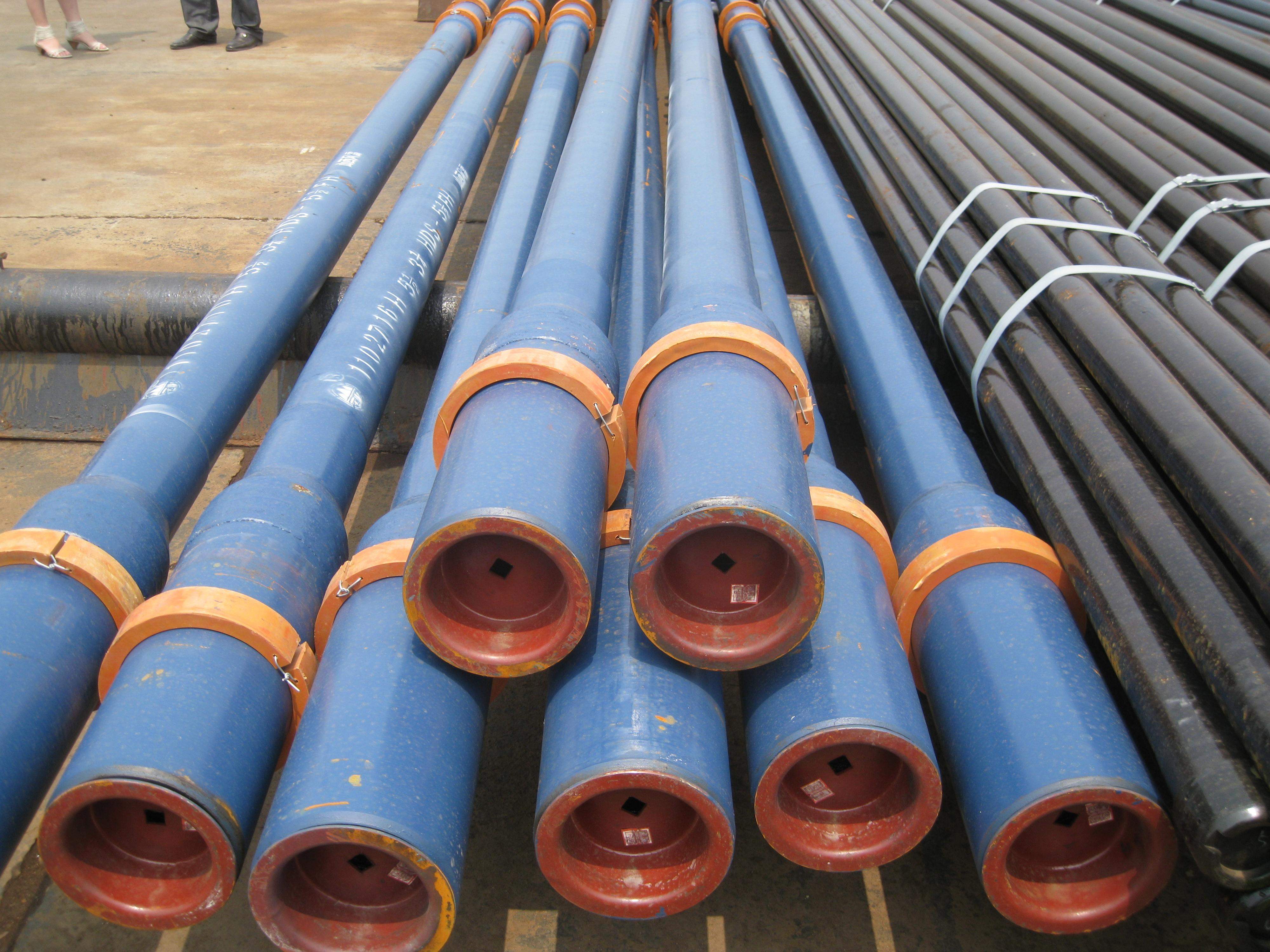

1.2.3: Tubing

These pipes are used after the wells are drilled and the tubes are used to fill the well to use the oil layer.These tubes have a smaller diameter than liners.

Bottom of the Tubings are installed into the oil layer in the ground and tubing sizes are usually about 1 – 2 7/8 Inch, and depend on well physical parameters these tubings are perforated. The perforated type used for transmission fluids into tubings.

|

|

|

Perforated Tubing |

Unperforated Tubing |

1.2.4: Liner Hanger

Aliner hanger is a device used in oil fields to hang liners within and oil well So that oil can be pumped out of the well, a liner is used to create a vacuum. Liners can be installed mechanically or hydraulically, depending on the well. Setting a hanger is a crucial part of the process of "completion" which is the preparation of an oil well for drilling. These tools is available in size of 7,5 and 4 1/2 inches.

|

Liner Hanger

|

|

Liner Hanger Packer |

Liner Hanger |

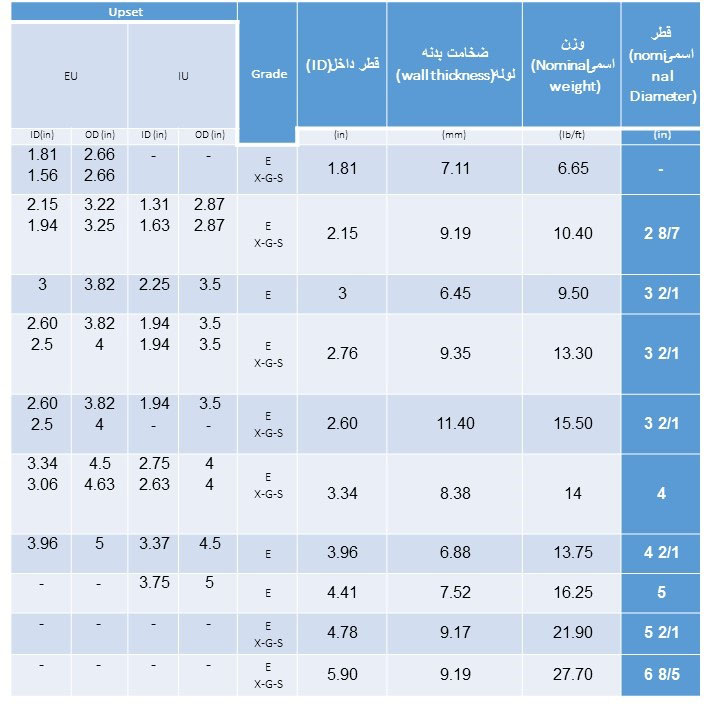

1.2.5: Drilling Pipes:

Drill Pipe, is hollow, thin-walled, steel or aluminum alloy piping that is used on drilling rigs. It is hollow to allow drilling fluid to be pumped down the hole through the bit and back up the annulus and these are most useful equipment in drilling operations is drilling pipes that its amount and sizes is vital. It is used in different sizes as2 7/8,3 1/2,5,6 1/2inch ,and with considering oil well profile position.

|

|

|

Drilling Pipe |

Drilling Pipe In Derrick |

Table4: Physical specification Drilling pipes:

1.2.6: Heavy Weight Drill Pipe

Heavy Weight Drill Pipe. (HWDP) may be used to make the transition between the drill collars and drill pipe. The function of the HWDP is to provide a flexible transition between the drill collars and the drill pipe. This helps to reduce the number of fatigue failures seen directly above the BHA.It is available in following sizes: 2 7/8,3,3 1/2,5, 6 1/2.

|

|

|

Heavy Weight Drill Pipe With Different Diameter |

1.2.7: Motor Turbine Drill and Positive Displacement Mud (PDM)

The positive displacement motor (PDM) has been used in directional drilling now for several years and is a key component in bottom hole drilling assemblies. These downhole drilling motors, coupled with Measurements While Drilling (MWD) tools and proper stabilization allow directional wells to be drilled with one bottom hole assembly, eliminating costly multiple drill string tripping, which in the past was necessary for surveying, hole corrections, and stabilized assemblies.

|

|

|

|

Downhole Motor PDM |

PDM Motors |

Downhole Motor |

1.2.8 :Jar Drill Pipe

Mechanical device used downhole to deliver an impact load to another downhole component, especially when that component is stuck.

There are two primary types, hydraulic and mechanical jars. While their respective designs are quite different, their operation is similar. There are available from 3 1/2 to 8 1/2 inch with high grade steel.

|

|

|

Hydraulic Jar Pipe |

1.2.9:Drill Collar:

A drill collar is a large-diameter, heavy pipe used in oil drilling that fits around the drill string and puts weight on the drill bitand it’s is the most widely used equipment after drilling pipes which have a very important role in well drilling, Because of high weight, It increases weight and drilling speed. These are available is sizes of:3 1/2,8 1/2,9,11,13ch and should be available on the rig.

|

|

|

|

Drill Collars with Different Diameters |

******************************

Ladiz Niroo Company (L.N.CO), with several years of experiences in field of supplying Oil & Gas industries Equipment has wide range activities in procurement of above mentioned equipment.